-

Produkty

-

Laboratorní přístroje

-

Laboratorní přístroje a elektrody

Řada HQ/Přístroje HQD/Sondy a elektrody Intellical Kalibrační standardy

- Chemikálie, reagencie a standardy

-

Online analyzátory

EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

-

Online senzory a kontroléry

Úprava vzorku

- Software a bezpečnost. systémy

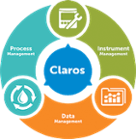

- Claros Water Intelligence System

- Vzorkování

-

Laboratorní vybavení a spotřební materiály

ZařízeníPřístroje Skleněné/plastové nádobyVšeobecný laboratorní spotřební materiálKnihy a referenční literatura

-

Mikrobiologie

Dehydrovaná média Laboratorní potřebyPřipravená média

- BART testery

- Kapalné MPN

- Kvasinky a plísně

- Membránová filtrace

- Média pro celkové počty

- Přítomnost-Nepřítomnost

- Zkumavka s MUG

- Testovací soupravy a proužky

- Automatizované laboratorní systémy

-

Laboratorní přístroje

- PARAMETRY

-

Softwarová řešení

-

Claros Water Intelligence System

Pilíře produktu Process Management

- Řešení pro :

- Odstraňování BSK/CHSK

- Nitrifikace/denitrifikace

- Odstraňování fosforu

- Řízení kalového hospodaření

Data Management- Řešení pro :

- Sběr dat

- Vizualizace a analýza

- Hlášení

- Přesnost dat

Instrument Management- Řešení pro :

- Údržba

- Odstraňování potíží

- Vzdálený přístup

- Porovnávání měření v laboratoři a procesu

-

Claros Water Intelligence System

- Odvětví

- SERVIS

- Novinky a události

Nitrification/ Denitrification. Under Control.

|

Hach’s off-the-shelf RTC-N/DN System adjusts nitrification and denitrification processes in real time, helping you meet ammonia and nitrate control limits while reducing money spent on excessive and unnecessary aeration. |

Controlling aerobic and anoxic cycles through ammonia and nitrate makes your process more consistent. The RTC-N/DN system continually monitors your mixed liquor ammonia and nitrate levels and responds automatically to load changes, keeping your facility compliant. Controlling your process has never been so simple.

An Off-the-Shelf System

RTC is a plug-and-play system that is ready to use after a very simple set up. Minimal downtime is needed to install the system and once installed Hach will help you program your setpoints so you are fully prepared to monitor and treat your water in real time.

Save Money on Treatment

The RTC-N/DN module is preprogrammed with algorithms that adjust blowers to maintain your desired DO setpoint based on ammonia and nitrate levels. By treating only when needed, you save on energy costs.

When We Say Service, We Mean Service!

Hach’s complete Service package includes routine maintenance visits and warranty repairs. A team of remote technical experts will monitor your system and send you reports so you know your system is working properly. It's like having a Hach Technician at your facility.

AMTAX sc: High precision process-instrument for the determination of ammonium in water, waste water and activated sludge. Outdoor enclosure. Incl. filter probe with 5m hose. 230V AC/50 Hz power supply.

- Automatic cleaning and calibration

- Wall mountable, rail mountable and mountable on a stand

- With integrated filter probe

- Many additional versions available on request

The sample preparation is done by an integrated sample preparation probe with 5 m heated hose. The filtration probe is operating at 230V. Evaluation and operation with SC 1000 Controller. The analyser is equipped with an insulated enclosure for outdoor installation. The sample can be analysed before any degradation. The ammonium in the sample is first converted to gaseous ammonia. Only the NH3 gas passes through the gas-permeable membrane of the electrode and is detected. This method guarantees a wide measuring range and is less susceptible to cross-sensitivity methods that make use of an ion-selective electrode (ISE). in situ membrane filtration; filter modules are exchangeable.

Back to the top.

SC 1000: Local measurement of several parameters

Probe module for connecting up to 4 SC sensors, with analogue output card with 4 x 0/4-20mA OUTPUT, relay card with 4 break contacts (NC), and EU power cord for 100-240V AC power supply.

- Flexible: individually configurable

- Future-safe: always expandable

- Intuitive operation: display with touchscreen

- Many additional versions available on request

A controller system to which SC sensors can be connected and from which they can be controlled consists of a single SC 1000 display module and one or more SC 1000 probe modules. The system is configured modularly in line with customer-specific requirements and can be expanded at any time with additional measurement stations, sensors, inputs, outputs and bus interfaces.

The probe module is used to connect SC sensors to a measurement station. Several probe modules can be linked to create a SC 1000 network.

Back to the top.

RTC-N/DN

RTC105 N/DN Module, 1-channel, intermittent, VFD control

Control module for load-dependant regulation of nitrification and denitrification times. 1-channel version for intermittently operating WWTPs. With DO step control (6x digital + 2x FU).

- Load-dependent aeration

- Stable nitrogen discharge values

- Reduced energy consumption

- Simple installation

The real-time controller optimises nitrogen elimination at biological waste water treatment plants that are operated either intermittently or in SBR mode (SBR reactors).

Based on the current ammonium and nitrate load, the module automatically calculates when aeration should occur and to what intensity, so that the required discharge values can be reliably met.

The run time of the blowers can also be reduced by setting the load-dependent nitrification and denitrification times, thereby lowering energy costs.

Back to the top.

AN-ISE: Combination sensor for ammonium and nitrate

AN-ISE sc with RFID Low cost ISE combination Ammonium and Nitrate probe (immersion), 10m cable

Carries out continuously direct measurements using an ion-selective electrode. No need for reagents or sample preparation. Compensated interference by potassium and chloride.

- Reliable results for ammonium and nitrate

- Easy handling with CARTRICAL plus

- Simple and intuitive operation

- Always under control

- Rely on Hach's application know how

The special feature of the probe is the CARTRICAL technology. This provides reliable measured values and considerably reduced maintenance time and costs in comparison with conventional ISE probes.

The complete system - SC controller has to be ordered separately - comes from a single supplier. The probe is installed on the side of the tank. The measuring system can be extended to include an automatic cleaning unit with a compressor.

Back to the top.

NITRATAX: Reagent-free method. Multiple beam absorption photometer with a flash lamp, turbidity compensation through reference measurement. Lowered directly into the sample stream (flow-through unit optional).

- UV absorption method-proven, continuous, and precise

- Eliminates reagents, sampling, and sample conditioning

- Self-cleaning probe

- Measurement in activated sludge or in water

- Life-long factory calibration

Stainless steel probe. UV beams are projected across a gap for immediate measurement of the nitrate content in water, wastewater and activated sludge. The measuring windows are cleaned by a wiper. Evaluation by SC controller. The simple mounting and easy handling of the probe is guaranteed by a specially designed tank rim mounting hardware. In order to place the controller near the probe, the tank rim mounting hardware for sc controller should be used. The through-flow variant is used wherever submersible installation is not possible for construction related reasons or the medium makes it necessary to measure a filtered sample (very high TS contents, sewage treatment plant inlet, etc.).

Back to the top.

LDO sc: The new LDO generation - even simpler, even more reliable and even more cost-effective

Immersion or flow-through probe with optical luminescence measuring method. Calibration-free & drift-free.

- Extremely reliable - 36-month warranty on probe

- The optimised temperature sensor and the new 3D factory calibration make O2 measurement even more accurate

- No electrolyte or membrane changes necessary

- Remote functions for simple and convenient data transfer via Internet and SMS

No electrolyte or membrane changes due to the optical measurement method. The new LDO probe ensures there is only a minimal amount of maintenance. The luminescence method means the measurement is unaffected by any type of interference.

Years of practical experience have shown that this method completely overcomes the disadvantages of traditional electrochemical O2 measurement methods.

Back to the top.

Intermittent wastewater treatment plants that use traditional time control systems have a significant drawback: they operate without taking the load into consideration. Aeration is activated or deactivated by the system for a predetermined period of time. Too much oxygen results in unnecessary energy costs and is also detrimental to denitrification. This figure illustrates the considerable differences between the ammonium and nitrate values produced by traditional time control system and those produced by differentiated control systems.

Intermittent wastewater treatment plants that use traditional time control systems have a significant drawback: they operate without taking the load into consideration. Aeration is activated or deactivated by the system for a predetermined period of time. Too much oxygen results in unnecessary energy costs and is also detrimental to denitrification. This figure illustrates the considerable differences between the ammonium and nitrate values produced by traditional time control system and those produced by differentiated control systems.

The limitations of traditional control systems become apparent every time there is load change, something that can happen several times a day. During low load phases, aeration cycles that are too frequent and too long result in an excessive oxygen concentration and slow down the denitrification process. The results shown in the diagrams were taken simultaneously, and in identical load situations, from two different automated scenarios. One set of results was taken from RTC–N/DN and one from a traditional time control system. This figure illustrated how steeply the nitrate value increases in the controlled scenario.

Eliminating ammonium load peaks from process water

Workers at the Kornwestheim treatment plant have been seeking to optimise energy consumption and reduce the nitrogen load in the outlet for many years. However, when using an aeration control system that is exclusively based on oxygen concentration values, these efforts have their limitations. When process water is added, the high ammonium peaks lead to an increase in the nitrogen load in the outlet.

Do you want to know what the solution is?

Read here the full application report.

High nitrate values during low-load periods

At the Villau treatment plant, the fixed time control for aeration could not be adapted precisely enough to handle the fluctuating load levels. This led to unnecessarily high nitrate values, particularly during low-load phases. In addition, energy consumption as a whole was too high.

At the Villau treatment plant, the fixed time control for aeration could not be adapted precisely enough to handle the fluctuating load levels. This led to unnecessarily high nitrate values, particularly during low-load phases. In addition, energy consumption as a whole was too high.

Do you want to know what the solution is?

Read here the full application report.

Workers at the Kornwestheim treatment plant have been seeking to optimise energy consumption and reduce the nitrogen load in the outlet for many years. However, when using an aeration control system that is exclusively based on oxygen concentration values, these efforts have their limitations. When process water is added, the high ammonium peaks lead to an increase in the nitrogen load in the outlet.

Do you want to know what the solution is?

Read here the full application report.

High nitrate values during low-load periods

At the Villau treatment plant, the fixed time control for aeration could not be adapted precisely enough to handle the fluctuating load levels. This led to unnecessarily high nitrate values, particularly during low-load phases. In addition, energy consumption as a whole was too high.

At the Villau treatment plant, the fixed time control for aeration could not be adapted precisely enough to handle the fluctuating load levels. This led to unnecessarily high nitrate values, particularly during low-load phases. In addition, energy consumption as a whole was too high.Do you want to know what the solution is?

Read here the full application report.

Stellen Sie sicher, dass Ihre Anlage effizient arbeitet und die Wasserqualität das ganze Jahr ohne außerplanmäßige Ausfallzeiten überwacht wird.

|

Für Messgeräte ist die Wartung genauso wichtig wie die Inspektion für ein Auto: sie spart auf Dauer nicht nur Geld, sondern garantiert einen störungsfreien Einsatz und zuverlässige Messergebnisse. Wir bieten flexible Wartungsverträge, die auf Ihre Bedürfnisse angepasst sind, sowie die Möglichkeit, die Gewährleistung auf bis zu 5 Jahre zu verlängern. |

Jetzt weitere Informationen anfordern!